There are times when I wonder why companies have purchasing departments. Wouldn’t it be a great cost reduction to get rid of the overhead for this group and just let designers pick suppliers and set component pricing? A demand planner could interface with contract manufacturers that would keep costs competitive and take care of all shortage problems.

This great idea has been tried in companies to varying degrees, and it doesn’t work because purchasing departments are adding value. To my thinking, they ensure the security and cost effectiveness of supply. How well they do it is what separates great purchasing departments from mediocre ones.

The data I see at Lytica shows that great purchasing departments save their companies 15 to 20 percent of materials costs compared to average ones. A 20 percent saving covers a lot of overhead. The great ones also function with less supply chain risk by having qualified alternate sources. The best companies focus on cost, know their market prices, and negotiate for results, while the unexceptional ones settle for “the usual” because security and cost effectiveness of supply are not real priorities for them until there is a major crisis.

Most companies operate between these extremes. I have seen companies discover cost reduction religion and improve their spending competitiveness by 15 percent within one to two years. What a great investment purchasing is!

Too many procurement departments are understaffed, forcing them to be quotation processors rather than negotiators. They transact without adding value. This may be one cause of the myth that pricing correlates with volume — something I have never been able to find in final client data. I accept that cost correlates with volume and might accept that un-negotiated quotation pricing may weakly correlate to some degree. I also observe that distributors love to show price vs. volume relationships. What I know is the exceptional procurement groups start with quotations and negotiate for results. They kill any price volume curve that may have existed.

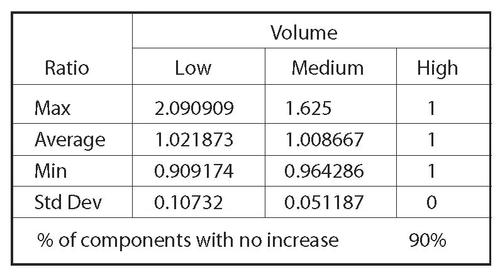

I have just completed a study on quotation pricing, which compares direct manufacturers’ quotes against volume, based on data from work done earlier this year for clients. The study analyzed quotations of 59 manufacturers across most electronic component commodities and involved 421 manufacturers’ part numbers. Each part was quoted at three volumes. The low volume was 50 percent of the middle value, and the high volume was 50 percent higher. The lowest annual volume used was 750 pieces, and the maximum volume was 21,285,000. Here is what I found when I normalized the data to have the three volume prices expressed as a ratio of the highest volume price:

This looks very flat and supports my assertion above of no relationship. On components where there appears to be a relationship, the low and medium volume prices can often be negotiated to the high volume price or better. This was the case with the max ratio component where we achieved the high volume price at the low 750-piece volume. Pricing depends on total spending (actual and potential) with a supplier, not on the spending of any single component.

My recipe for turning ordinary purchasing departments into great ones is simple: Start negotiating. Successful negotiators know the market value of their components, have targets, and maintain leverage with supplier options. Every purchasing professional who deals with electronic components should have a New Year’s resolution to focus on this lost material savings for their company. Abandon price vs. volume constraints and get great results. Domestic companies could benefit from this boost to competitiveness and profit.

If you choose to remain ordinary, answer these questions:

- Have you ever had a supplier maintain pricing when volumes dropped significantly?

- Has a supplier ever asked what price it takes to win your business?

- Have you ever negotiated a better price than you started with?

If you answered yes to any of these questions, you have proven that the mythical price-volume curve doesn’t exist.

If you are forced to be average because of budget constraints, show this blog to your boss. Most companies can do better if they let their procurement groups perform. If you want fast results download the Fast Track Cost Reduction whitepaper from the Lytica resource website.

By Ken Bradley – Lytica Inc. Founder/Chairman/CTO